機器介紹影片

- PlateRite Ultima 40000/36000

SCREEN has dedicated itself to developing advanced technology that is a step ahead, so that we can consistently offer optimal solutions that streamline processing while improving productivity and quality.

The crystallization of SCREEN’s efforts in the CtP field is our latest large-format thermal platesetters, the PlateRite Ultima 40000/36000.

- GLV™ imaging head with high-power laser

GLV™ (Grating Light Valve™) technology employs the same production processes as those used in semiconductor manufacturing. A GLV™ array is made up of thousands of microscopic reflective ribbons placed over a silicon chip.

These ribbons can be moved up and down to either reflect or diffract the imaging laser that is targeted at the array, and thus simultaneously turn on and off an extremely high number of optical channels.

SCREEN utilizes the laser control technology that has been cultivated over the years to target a high-power laser at the GLV™ array with extremely high precision, making it possible to simultaneously control 512 channels of light.

These 512 channels can expose the image for each rotation of the drum and contributes to much higher productivity.

The combination of a high-power laser and GLV™ technology delivers sharp and clear halftone dots, which is the core technology of the PlateRite Ultima 40000/36000 to meet the stringent demands of SCREEN’s clients.

- Automatic inline plate punching for extremely high registration accuracy

The PlateRite Ultima series features an automatic inline punching system that helps eliminate misalignment caused by improper plate positioning, and results in superior registration accuracy. When optional press punch blocks are used (up to 10 punch blocks can be mounted and selected according to the plate size and press type), the imaged plates can be loaded directly onto the press after output. The use of press punch blocks during plate output eliminates the need of manual punching afterwards, ensures excellent registration accuracy, and creates the foundation of the perfect results on press. It also dramatically shortens press make-ready time and improves press operating ratios for even better overall productivity.

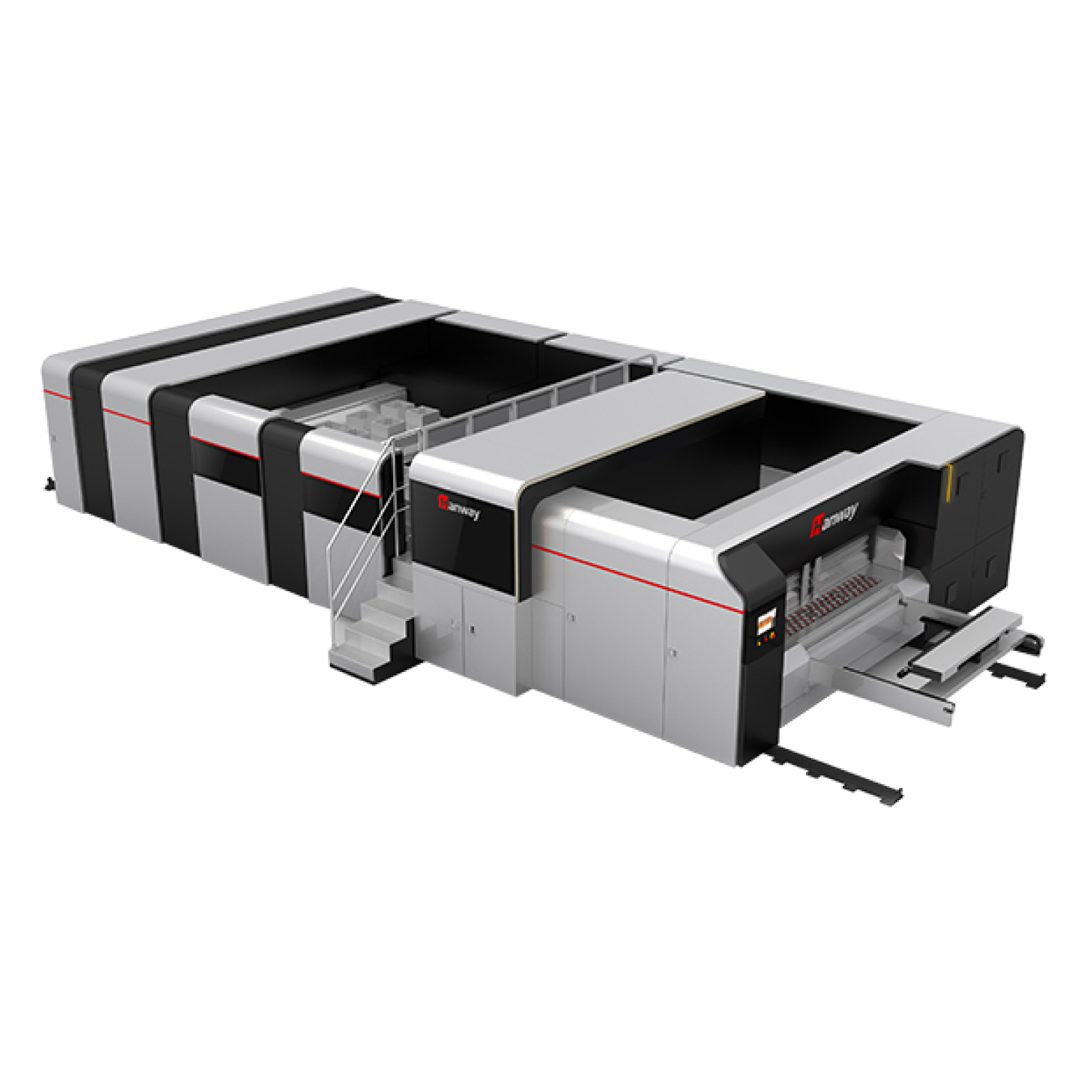

- Automated plate loading for very large format plates

Mounting larger and heavier plates not only becomes the burden on the operator but also reduces the efficiency of the CtP production line, since the use of larger plates increases the risk of damaging plates when handling and much time is required for loading operations. Automatic plate loading is critical to ensure the stability of the CtP operations when using large-sized plates. The PlateRite Ultima 40000/36000 can be fitted with the optional MA-L40000 and/or SA-L48000 Skid automatic plate loaders, both featuring the PlateRite series’ renowned plate transporting technology. We also offer solutions to connect 2 autoloaders to one CtP. These automatic plate loaders make it possible to create a fully automated production line.

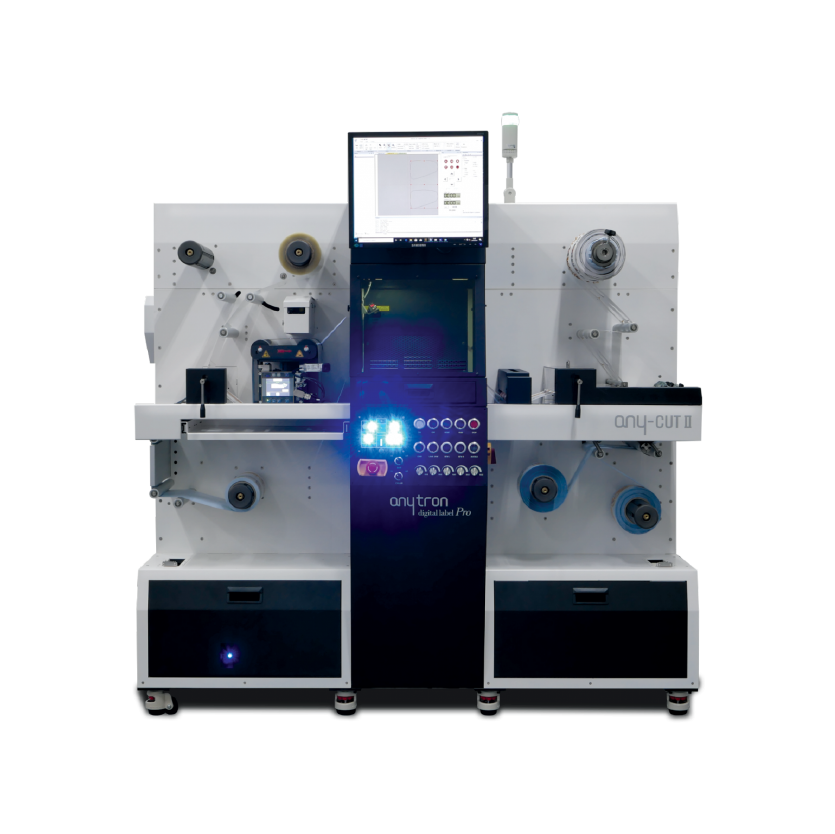

- Dual plate imaging (option)

The advanced PlateRite Ultima 40000/36000 can image two plates together on the drum. The PlateRite Ultima 40000/36000 can image two plates of maximum 1,060 x 1,600 mm together.

In other words, these platesetters are perfect for imaging not only large-format plates but also pairs of smaller plates at once.

Imaging pairs of plates increases productivity since the number of loading and unloading plates can be reduced. Twin imaging heads can be used to simultaneously expose two plates set side-by-side for even higher productivity.

下載 PDF (中文版)關於SCREEN日本網屏

下載 PDF (中文版)關於SCREEN日本網屏網屏作為世界頂尖的製版設備製造廠商,一向致力於生產品質可靠、品質卓越的印前製造設備。產品多元化,包括電分機、掃描器、伺服器、印前工作站、輸出機、打樣機和電子雕刻機等。 網屏(中國)於1983年在香港設立總部,目前在北京、上海、廣州均設有分公司,主要負責市場推廣,提供客戶售後服務和技術培訓予國內。網屏一向致力發展高科技產品,不斷為圖像製作帶來更新、更優良的技術及產品外,更非常強調完善及專業的客戶服務,不停作出全面及針對性的技術支援,百分百擔當卓越服務的承諾。

更多細節請參閱