機器介紹影片

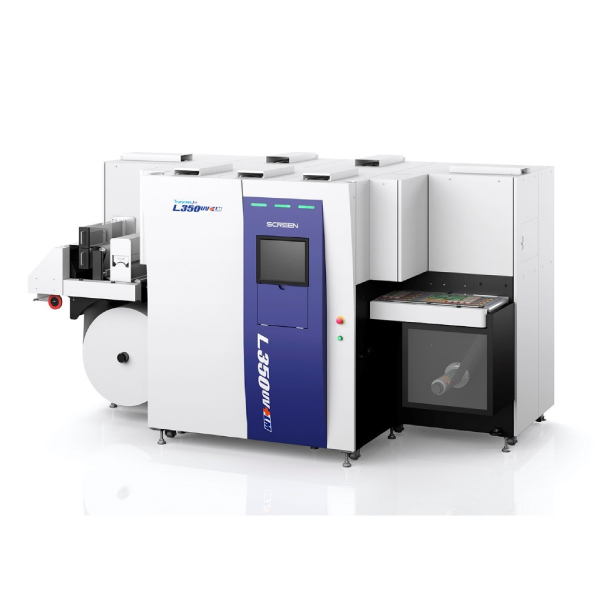

- PlateRite FX1524N/FX1200N

The PlateRite FX series are high-quality, easy to use, reliable CtP recorders that offer optimal flexo/letterpress plate output for printing and prepress companies.

They can image the black mask layer of resin plates directly, thereby eliminating the need for film and other intermediate processing. This results in more efficient operations, as well as more consistent output quality. What’s more, their superior halftone dot reproduction ensures consistently high-quality printing even in the highlight and shadow areas.

The PlateRite FX1524N/FX1200N is designed for a wide range of uses, including the production of labels, flexible packaging, cartons, and corrugated packaging.

The PlateRite FX1524N and FX1200N eliminate many of the problems associated with platemaking using film, including image unevenness, problems caused by dust, and UV scattering. They also solve problems inherent in going from film to plate, such as misalignment of the film during platemaking and registration errors arising from stretching of the film. This helps to ensure consistent plate quality and reduces wastage with fewer plates having to be re-output due to errors.

The light source used by the PlateRite FX series, a multi-channel laser diode, is the same type of laser as those used in SCREEN's traditional offset CtP recorders. This proven, reliable, high-powered laser images the black mask layer of resin plates. In addition to enabling sharp imaging, the PlateRite FX series’ light source is both long-lived and inexpensive to operate.

- 4,800 dpi resolution for high-quality output

The PlateRite FX1524N and FX1200N offer a maximum output resolution of 4,800 dpi. This high resolution significantly reduces the incidence of problems common in low-resolution output, such as jaggies in diagonal lines and curves, and dramatically improves the repeatability of fine line reproduction. 4,800 dpi output also delivers smooth gradations, and almost completely eliminates unevenness, even in the highlight areas.

Furthermore, newly developed Super Fine Cell function forms minute indents in the plate surface that are used to retain ink, enabling a higher volume to be transferred. This function is particularly effective for increasing ink density in solid areas.