機器介紹影片

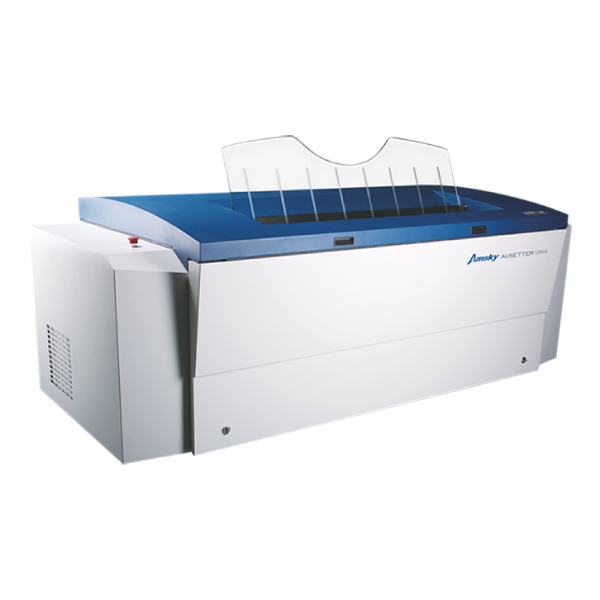

- PlateRite Ultima 16000N

- High Productivity - Up to 42 plates per hour

- Automation - Maximizes operating ratios

- Ecology - Approx. 53% less power use during operation

- Support - Boosts operational stability

- Industry-leading productivity enables faster turnaround

Use of the the GLV-equipped imaging heads creates significant improvements in the optical system, producing more uniform distribution of illumination. A high-precision auto-focus mechanism also allows the output of our proprietary Spekta 2 hybrid screening and Randot X 20 (20 μm) FM screening. The Z model is equipped with a 1,024 channel imaging head that enables the production of an impressive 42 plates per hour. The S and E models also feature 512 channel heads, with respective throughputs of up to 29 and 17 plates per hour.

- Skid and multi-cassette autoloaders

All 3 models are fully automated by connecting SA-L24000SKID or MA-L16000NII autoloader. The newly released skid loader, SA-L24000SKID, for the PlateRite Ultima 24000N is also available for the PlateRite Ultima 16000N series. Maximum 600 plates* can be mounted on a pallet and it can be set directly in the skid loader.

The multi-cassette autoloader, MA-L16000NII, has 3 cassettes for different plate sizes and can be upgraded to 6 cassettes as an option. Each cassette holds up to 75 plates and can supply maximum 450 plates* to the CtP.

Both autoloader systems greatly contributes to continuous operation, maximizing the efficiency of the whole printing process.

* For 0.3 mm thickness plates

- Gentle on the environment

We assess the environmental impact of all our products as a form of design review. The PlateRite Ultima 16000N series has been developed with the goals of minimizing energy use and environmental impact while maximizing safety.

• Energy use during operation is reduced by up to 53%.*

• A power-saving mode allows energy savings during idling.

• Energy use during standby is reduced by up to 84%.*

• All models are compatible with chemical-less plates from a range of manufacturers.

• The use of a registration punch-less system cuts running costs.

* A comparison of the PlateRite Ultima 16000 and PlateRite Ultima 16000N-Z when a plate insertion table is used.The test involved imaging high-sensitivity material of 1,470 x 1,165 mm (57.8" x 45.8"). As power consumption is also affected by the operating environment and other external factors, the above values cannot be guaranteed.

- Advanced support boosts system reliability

Users can easily monitor and control their system from a remote location via Web browser or e-mail.* An external PC can also be effectively used as a substitute operation panel to manage CtP settings. E-mails are automatically forwarded to a service center, providing an in-depth understanding of the operation status of the equipment. This information can be used during maintenance and periodic inspections to ensure the system remains in optimal condition at all times.

* Can be forwarded to up to five e-mail addresses